Waterslide Transfer Decal Paper

Water transfer paper needs to be soaked in water before use. Firstly, use water to separate the pattern from the backing paper. Then transfer to the objects. Finally, it realizes indirect printing. So waterslide decal paper is new transfer technology.

1. What is waterslide decal paper?

The base paper of water slide decal paper is water transfer paper. Because the surface is with water-soluble adhesive, it is particularly absorbent. So needs to wet the paper first.

After the surface pattern is separated from the base paper, attach the transfer paper to the object. Then peel off the backing paper.

Susunod, wipe away moisture and air bubbles. After completely dry, the stickers sticks strongly to the object.

2. Technical specifications of water transfer paper:

Available type: screen printing, inkjet and laser decal paper;

Available paper weight: 160GSM, 170GSM, 175GSM, 180GSM, 185GSM, 195GSM;

Regular size: A3, A4, 390*540mm, 457*590mm, 500*600mm, 500*700mm, 600*800mm;

Waterslide decal paper color: white and blue;

Best humidity in the printing workshop is 40~50;

Best storage humidity≤30;

Release time: less than 40 segundo;

Water transfer paper application: karamik, salamin, helmet, bisikleta & bike frame, kahoy, laruan, modelo, kandila, tarong, carbon fiber material, musical Instruments & guitars, Temporary tattoo na sticker, baseball bat, at iba pa;

Technical data of water decal paper:

| Item | Unit | Specification | Remarks | |||||

| Base Weight | GSM | 170±2 | 175±2 | 180±2 | 185±2 | |||

| Kapal | μm | 200±5 | 205±5 | 210±5 | 215±5 | |||

| Gum Coat Weight | GSM | 3GSM | 3GSM | 3GSM | 3GSM | |||

| 75° Gloss | % | ≥75 | ≥75 | ≥75 | ≥75 | |||

| Moisture | % | 50±5 | 50±5 | 50±5 | 50±5 | the moisture can be customized according to customer’s requirement. | ||

| Release Time | sec. | less than 40 sec. | less than 40 sec. | less than 40 sec. | less than 40 sec. | |||

| Paper Sheet Size Deviation | mm | ≤0.3mm | ≤0.3mm | ≤0.3mm | ≤0.3mm | |||

3. Features of water transfer decal paper:

Water decal paper can print images on any solid medium. Its biggest advantage is that it does not require special equipment. Moreover, it is not limited by the medium. No need special consumables. Besides, also not require high temperature heating. In addition, printing images are colorful.

(1) Extensive application

Conventional printing has disadvantages. For example, it can’t be suitable for workpieces with complex shapes. But waterslide decal paper can solve this problem.

We can use water transfer paper on any curved surfaces. Moreover, it’s applicable for many different materials. Except cloth, it can basically be suitable to any other material.

(2) Beautiful stickers

The surface of water slide decal paper is smooth and delicate. Besides, there is no unevenness. The glue layer is uniform. Bukod pa rito, there is no glue leakage. Thus, the printing coloring rate is good. And overprint is accurate. Finally, the water decals have bright colors.

We can transfer any natural textures and photos onto the product. In addition, ceramic baked decals have no film shadow.

(3) Personalized and efficient

We can design any pattern freely. Besides, it doesn’t need plate-making. Drawing directly. Then transfer immediately.

In addition, the release time of water transfer paper is fast. About only 30 segundo. Moreover, it has good sliding performance. So the whole process takes only 30 minutes to complete. It’s also especially suitable for DIY products.

4. Waterslide decal paper applications

Water transfer paper can decorate most items, such as plastic, metal, salamin, karamik, kahoy, at iba pa. Simple and convenient operation. It is mainly includes the following two types:

(1) tearable water sticker

That is, there is transparent film layer on the decals surface. Besides, it needs to tear off this film. Finally, leave the pictures on the product.

This kind water transfer decals have following applications. Such as glass, ceramics, enamel, metal, at iba pa.

For example, print decals on ceramic tableware, cups and dishes. In addition, also use waterslide decal paper for ceramic tiles.

Halimbawa, print water decals for glass bottles and perfume bottles.

And we can also print waterslide decal paper for bicycle and motorcycle pipe fittings;

Bukod pa rito, water transfer decal paper has wide application for motorcycle helmets and hard hats.

(2) No tear-off water decals

That is, it doesn’t tear off the clear film. Or this is no the transparent protection film.

For example, we usually print decal paper as temporary tattoo decals. Moreover, use the paper for phone cases and handicrafts.

Halimbawa, apply the waterslide decal paper to decorate candles. In addition, print decals for toy car models.

Bukod pa rito, water transfer paper decals have other two kinds. That is, high temperature and low temperature water decals. The baking temperature mainly bases on how much temperature the material can withstand.

For example, ceramic decals can use both high temperature and low temperature. We can fire them at 1200℃ or 800℃. A low temperature of 200°C can also be used. Of course, the pattern of this low temperature decal is not permanent.

5. How to use or apply water transfer paper?

Water transfer paper stickers are easy to use. But many people handled improperly during the transfer process. Finally, it affects the aesthetic function of the water decals. So below is the use instructions of waterslide decal paper.

(1) Firstly, cut out the water decals. Then soak in warm water at 25 to 40℃.

(2) Secondly, take out the decal paper after about 30 segundo. At this point, you can slide pattern across base paper. That is, it has been separated from the backing paper. Because the soluble glue melts, the waterslide decal paper becomes slippery.

(3) Thirdly, clean the object surface. Pagkatapos ay, drag the base paper with one hand. Hold the pattern with the other hand. So you can attach patten onto object surface.

Align position. Then scrape off the water under the pattern layer. So it can keep the pattern close to the surface. Finally dry off the water. At this time, it completes transfer printing.

(4) In the end, let the decals dry naturally. Then we can start to carry out baking. Make sure to dry thoroughly. Otherwise, there will be bubbles after baking.

Of course, you can also paint some vanish on the water transfer paper. So the patterns will have durable adhesion.

6. How is water transfer paper manufactured?

Deal paper can realize the transfer of graphic printing. Water transfer paper is based on special backing paper.

It carries out glue printing three times on the base paper. Finally, there form a pigment coating, a separator adhesive layer and a soluble adhesive layer. Among them, the latter two layers are both water-soluble. And the last layer has good sliding property.

After printing, water get the waterslide paper decals. Firstly, the patterns are separated under water pressure. Then transfer patterns onto product surface.

Water transfer paper manufacturing comprises the following steps:

Firstly, prepare the base coat, top coat, and back coat separately. Among them, the primer coating is made by mixing potato starch and water. The surface coating is the mixture of cornstarch and water.

Second, apply the primer coating to the pigment-coated surface of the waterslide decal paper;

Thirdly, apply the surface coating to the surface of the primer coating;

Finally, apply the backcoat to the back of the water transfer base paper. Then it get the decal transfer paper.

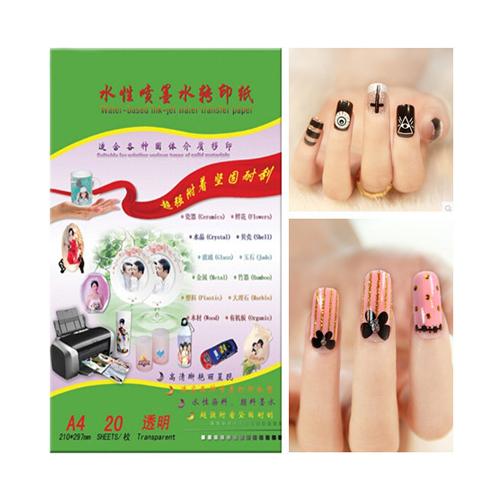

7. Clear vs white waterslide decal paper

For the printable decal paper, it mainly includes two types. That is, clear and white decal paper. In fact, inkjet and laser water transfer paper also include these two types. So what’s their differences?

(1) clear water decal paper

It is also transparant paper. And it can suitable for both inkjet printer and laser printer. There is no white ink on the paper. It is suitable for transparent items, such as crystal, salamin, at iba pa. Also suits for white or light color items. So this paper has most wide applications. It can reveal the object’s own background color and shading.

Applications: salamin, karamik, kandila, marble table, mobile phone case, toy model, helmet, at iba pa. In addition, nail stickers and tattoo decals also use transparent water transfer paper.

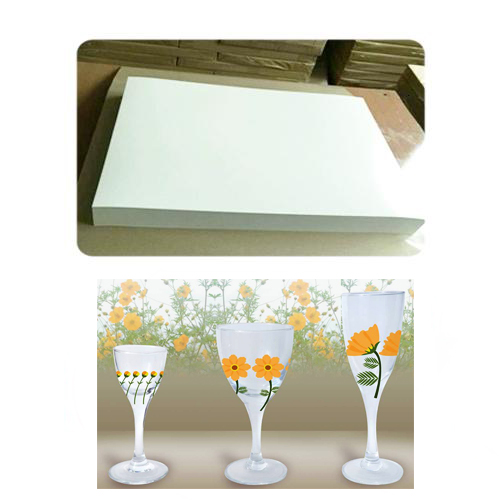

(2) white decal paper

This paper is not transparent. The substrate and transfer film are white. There is a layer of white ink on the surface. It can hide the color of the product itself. Therefore, it is suitable for dark or black items. The transfer pattern will be clearer. In addition, it can make glass products appear opaque after transfer printing.

Applications: mouse, black mug, dark helmet, carbon fiber material, dark toy model, tumbler, etc.;

(3) the diffrence between clear and white paper

How to distingush these two water transfer paper? Compare the two types of paper. You’ll find that white paper has a higher gloss than clear paper. You can also rub some water on the paper. If you can feel the ink, then it’s white decal paper.

Jim

Jim

Sales Manager

Sales Manager