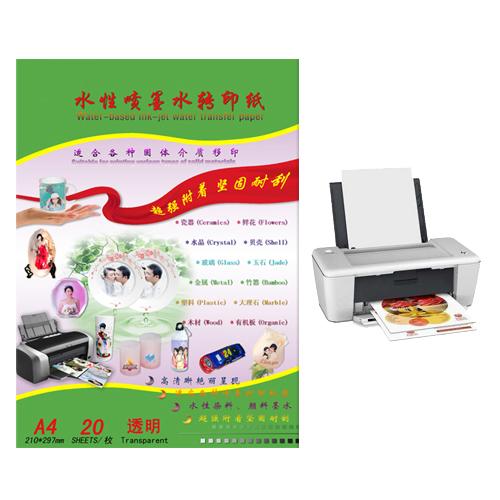

A4 tiszta tintasugaras víz csúszdamatrica papír kerámia bögrékhez

KATEGÓRIA ÉS CÍMKÉK:Tintasugaras vízcsúszda matricapapír

1. Good ink compatibility

2. Print quality, currently supports up to 5760dpi resolution;

3 anti-fading: do not fade;

4. Film toughness: good;

5. Adhesion: super strong after baking;

6. Regional Climate: Unlimited;

7. Ink absorption layer oxidation: no oxidation;

8. Stability: 3 years of original quality;

- Műszaki adatok

It is very easy to use the inkjet water slide decal paper to make your own personalized ceramic mugs.And it is important to select good quality of inkjet water slide decal paper for ceramic mugs.Many poor decal paper doesn’t absorb ink and their printing effect is not stable.At some times,akkor is elhalványul, ha a festéket egyenletesen permetezik.

Info of inkjet water slide decal paper for ceramic mugs:

Decal paper type:clear/transparent;

Papírméret:A4(210*297mm);

Suitable printer:any inkjet printer;

Suitable print ink:any water-soluble dye ink/pigment ink(ordinary ink);

Features:colorless and transparent,suitable for white color or light color objects,and it can reveal the background color of objects;

Advantages of our inkjet water slide decal paper for ceramic mugs:

1. Good ink compatibility

2. Print quality, currently supports up to 5760dpi resolution;

3 anti-fading: do not fade;

4. Film toughness: good;

5. Adhesion: super strong after baking;

6. Regional Climate: Unlimited;

7. Ink absorption layer oxidation: no oxidation;

8. Stability: 3 years of original quality;

How to apply the inkjet water slide decal paper for ceramic mugs:

1) choose one picture you design by yourself or any picture you download from the Internet.

2) print it (any inkjet printer and any ink can be used directly, laminating machine is no need.)

3) use a hair drier to dry it or natural air dry(5 minutes)

4) using the transparent gloss paint to spray evenly in the pattern surface.(you can get transparent gloss paint in the paint shop.)

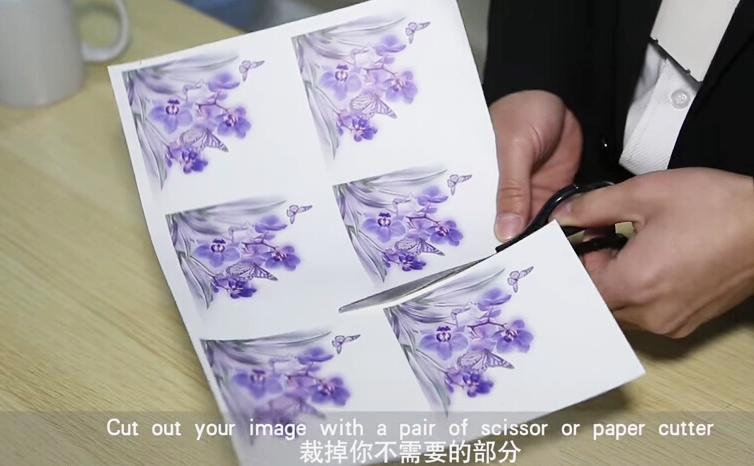

5) dry it and cut it.

6) put it into the water. After 30-60s, remove the transfer membrame 0.5cm first from the base paper.

7) put the 0.5cm picture first onto the ceramic mugs surface then pull the water slide transfer base paper away slowly.

8) clean the bubble under the transfer membrame with a brush. use soft cloth or absorbent paper to scrape the surface.

9) If time is limited you can use a oven to dry it 10-15 minutes with 100°C. If the material is plastic, 50-70°C is all right. If time is enough, hair drier also can be OK.

Jim

Jim

Értékesítési vezető

Értékesítési vezető