Best Water & Sublimation Transfer Paper Manufacturer

Chinese National Standard of Water Transfer Printing Paper

March 15, 2018

This standard formulates the classification, requirements, test methods, inspection rules, signs and packaging, transportation and storage of waterslide transfer printing decal paper.

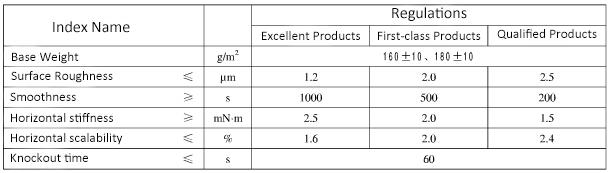

1.According to quality,the waterslide decal paper is divided into excellent products, first-class products and qualified products.

2.Requirements:

A)the technical data should in accordance with the below form or contract:

B)The waterslide decal paper can be sheet format and roll format.The sheet format sizes are 390*540mm,500*700mm,600*800mm,or custom.The size error must not exceed ±0.5mm and the skewness must not exceed 2mm.

C)For the waterslide decal paper,there should be flat surface,no obvious curl.There is no pleat,wrinkles, streaks,spots on the paper surface.And there should be no appearance defects of obvious pinhole leakage on the glue surface.

3.Test Methods:

A)Standard atmospheric conditions:(23±1)℃,Relative humidity:(50±2)%;

B)Make measurement to size and skewness according to rule GB/T 451.1;

C)Make measurement to base weight according to rule GB/T 451.2;

D)According to rule GB/T 22363,make measurement to surface roughness with pressure 981kPa and hard pad;

E)Make measurement to smoothness according to rule GB/T 456;

F)Make measurement to horizontal stiffness according to rule GB/T 22364;

G)Make measurement to horizontal scalability according to rule GB/T 459,and soaking time is 15 minutes;

H)Knockout time is measured according to appendix A;

J)Measure the appearance quality with visual inspection;

4.The mark,package,transportation and storage:

1)There should be plastic paper sealed packaging for the mark and package of water transfer printing paper;

2)When transportation,it should ensure Rainproof and moisture-proof,and keep clean;

3)When handling the water slide decal paper,it avoids dropping from height and rolling;

4)The waterslide decal paper should be storaged in the dry, ventilated and clean place.

To store the screen printing water slide decal paper well,it needs to prevent extrusion;

Maybe you like also

Copy©2008 | WTP| Sitemap

Jim

Jim

Sales Manager

Sales Manager