High Temperature Water Transfer Decals for Ceramic Tiles

CATEGORY AND TAGS:Water Transfer Decals, Water Transfer Decals for Ceramics

Sampling time of ceramic tiles decals:one week

Color:normal color or gold color tiles decals

Decal type:on glaze ceramic decals

Firing temperature:tiles decals for fire temperature 850c

Application:ceramic tiles for floor,wall or bathroom

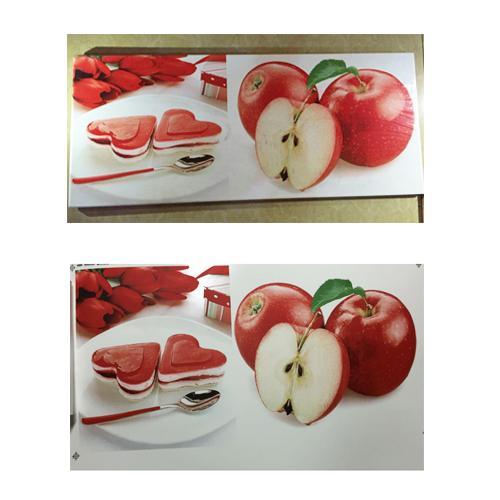

Ceramic tiles decals pattern:apple or custom patterns

- Specifications

Water transfer ceramic decals are important decoration material for ceramics.Our factory has rich experience in production all kinds of decals for domestic ceramics,sanitary ware ceramics and ceramic tiles.Our water slide transfer decals for ceramic tiles have good quality and wear resistance.

Material:water slide transfer decal paper

Paper base weight:175gsm or others

Process Size:390*540mm,500*700mm

Sampling time of ceramic tiles decals:one week

Color:normal color or gold color tiles decals

Decal type:on glaze ceramic decals

Firing temperature:tiles decals for fire temperature 850c

Application:ceramic tiles for floor,wall or bathroom

Ceramic tiles decals pattern:apple or custom patterns

The features of water slide decals for ceramic tiles:

1.The pattern is vivid and colorful;

2.Ceramic tiles decals sample is avaiable;

3.Scratch resistant and strong adhesion;

4.Knockout speed of paper is quick;

How to use water slide transfer decals for ceramic tiles:

Stage 1: Wipe the ceramic tiles that you want to stick clean (no duration time requirement, clean is ok).

Stage 2: Cut one pattern from the 50cm*70cm water transfer decal paper (no duration time requirement, cutting well is ok).

Stage 3: Soak and wet the pattern completely in water (wet completely is ok), warm water(20C-30C) needs to be used in winter.

Stage 4: Place the pattern onto the correct position of the ceramic tiles, wait for 1-2 minutes before moving the base paper, If not movable, wet completely again. If movable, move the base paper away carefully in one direction.

Stage 5: After moving the base paper, the pattern has been transfer printed on the ceramic tiles, then squeeze out completely any excess water and air bubble with rubber or other tools (no duration time requirement, squeezing out completely is ok).

Stage 6: Dry the water around the pattern with dry tiles(no duration time requirement, dry is ok).

Stage 7: Place the ceramic tiles has been printed pattern into a oven, then curing(baking) time in small oven is 2 hours ( from heating to cooling), the curing temperature is 780C-850C.

Noted; The high temperature ceramic decals need positive stick, that means the side of the pattern must face up or face to the operator(users).

Jim

Jim

Sales Manager

Sales Manager