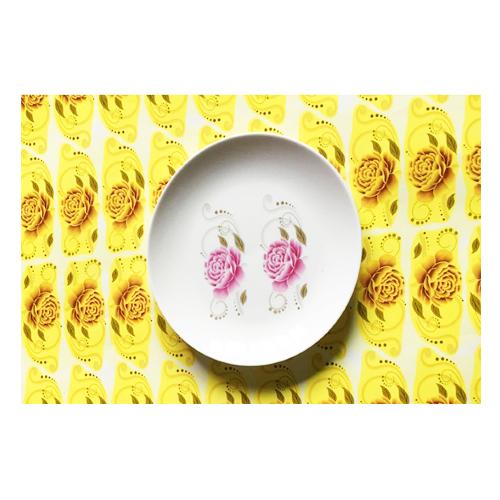

Flower Pattern Water Transfer Decals for Ceramic Dishes

KATEGÓRIA ÉS CÍMKÉK:Vízáteresztő matricák kerámiákhoz

1.High temperature firing decals for ceramics;

2.Environmental non-toxic;

3.The ceramic decal patterns are vivid;

4.Scratch resistant and strong adhesion;

5.Knockout speed of paper is quick;

- Műszaki adatok

A ceramic decal is used to apply designs to ceramic tableware, ornamental ware and tiles, and ceramic containers.

The waterslide transfer decal for ceramic dishes comprises three layers: The color, or image layer, which comprises the decorative design; The covercoat, a clear protective layer, which may incorporate a low-melting glass; And the backing paper on which the design is printed by screen printing.

Material:water slide decal paper

Paper baseweight:175gsm

Size:390*540mm,500*700mm

Printing:silk screen printing

Decal type:high temperature

Firing temperature:540-1300℃

Application:kerámia,ceramic tableware,ceramic dinnerware,ceramic plates

Ceramic decal customization:yes,it needs to supply the pattern of decals for ceramics

The features of waterslide decals for dishes:

1.Environmental non-toxic;

2.The ceramic decal patterns are vivid;

3.Scratch resistant and strong adhesion;

4.Knockout speed of paper is quick;

The application way of waterslide transfer decals for ceramic dishes:

Stage 1: Wipe the ceramic dishes that you want to stick clean (no duration time requirement, clean is ok).

Stage 2: Cut one pattern from the 50cm*70cm high temperature decal paper (no duration time requirement, cutting well is ok).

Stage 3: Soak and wet the cutted pattern completely in water for 3-5 seconds (wet completely is ok), warm water(20C-30C) needs to be used in winter.

Stage 4: Place the pattern onto the correct position of the ceramic dishes, wait for 1-2 minutes before moving the base paper, If not movable, wet completely again. If movable, move the base paper away carefully in one direction.

Stage 5: After moving the base paper, the pattern has been transfer printed on the ceramic dishes, then squeeze out completely any excess water and air bubble with rubber or other tools (no duration time requirement, squeezing out completely is ok).

Stage 6: Dry the water around the pattern with dry towel (no duration time requirement, dry is ok).

Stage 7: Place the ceramic dishes has been printed pattern into a oven, then curing(baking) time in small oven is 2 hours ( from heating to cooling), the curing temperature is 780C-800C.

Noted; The high temperature ceramic decals need positive stick, that means the side of the pattern must face up or face to the operator(users).

Jim

Jim

Értékesítési vezető

Értékesítési vezető