How to DIY Make Water Transfer Decals

March 17, 2018

Many model players hope that they can make some water transfer decals with their own personal patterns in order to make the models more personal.

This article is the introduction of how to make water transfer decals and use the inkjet water slide decal paper.Its size is A4.Of course,the use instruction of laser water slide decal paper is similar.

This kind of water slide decal paper can be printed by an ordinary household printer without any requirement for the printer and the ink.

Roughly talk about the production process:

Step 1: Make your own water transfer pattern;

Step 2: Export (Print) to Water Transfer Paper;

The third step: Since the inkjet ink is water-based (in the case of water), we need to spray clear lacquer for the protective layer;

Step 4: Soak the water transfer paper to separate the pattern from the paper and attach it onto the object.

======== Water Transfer Production Introduction Begin ============

Inkjet water transfer paper is divided into two kinds:

One is the white base(suitable for deep color or black objects);

Another is clear(suitable for white or light color objects).

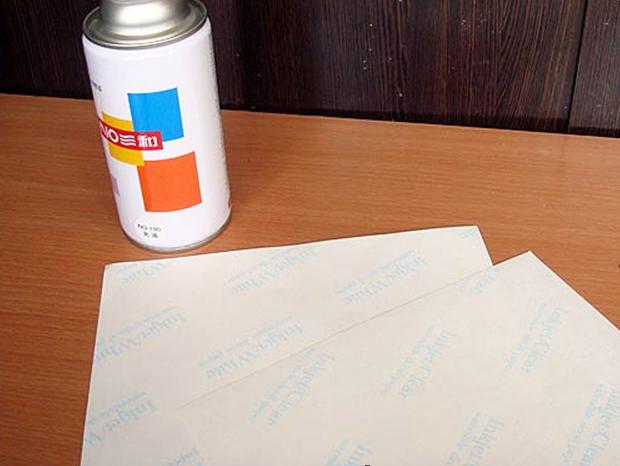

About the protective paint, I use domestic SANO brand light oil irrigation.

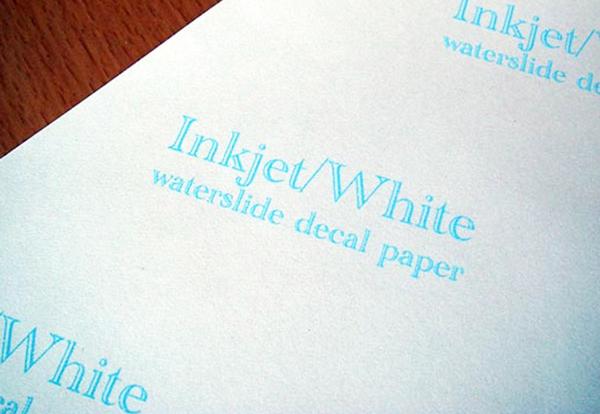

Below is the white base inkjet water slide decal paper:

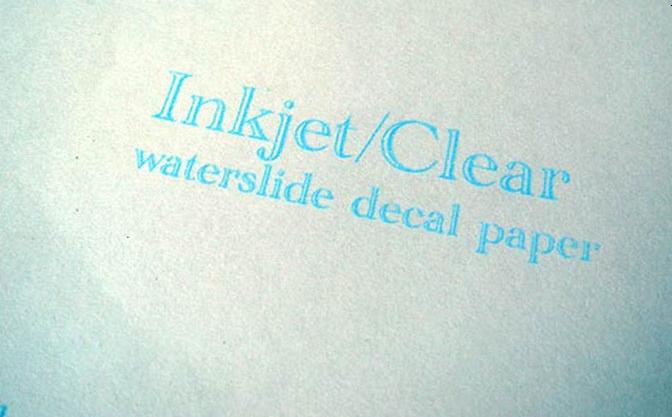

And this is the clear inkjet water slide decal paper:

The two kinds of water transfer paper surfaces are exactly the same. So add the English mark on the back.

Now begin to make a water transfer pattern!!!

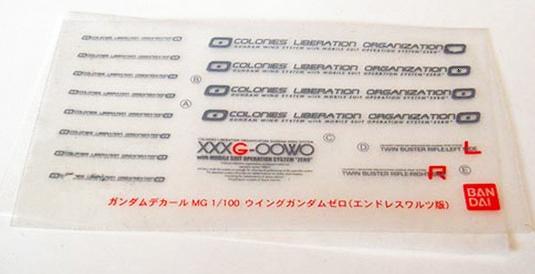

Take a sample of WING KA pressure sticker from Bandai.

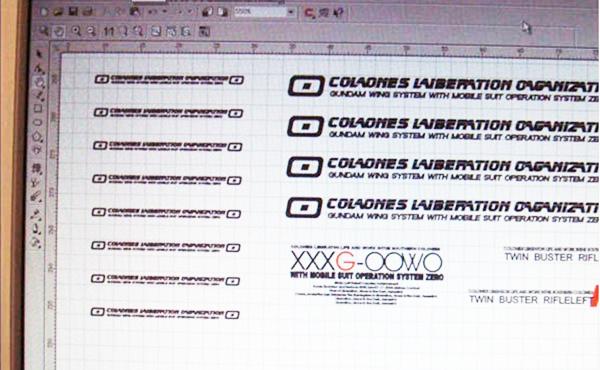

First draw the water transfer pattern,size and color we want on the computer.

Let’s talk about the pattern here. Scanning the water transfer output is not a good method, the resolution is not high, and the effect is much poorer.

About the pattern output,use the vector output as much as possible, and the user draws the required figure by software.

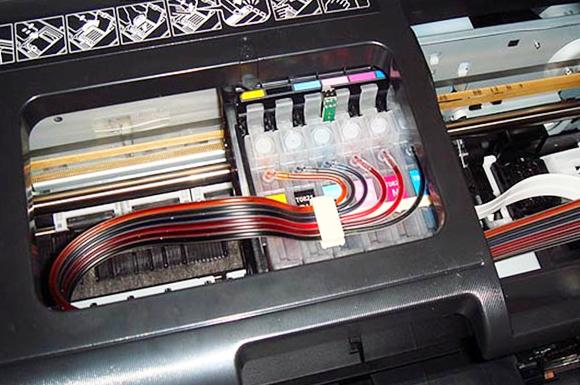

Then it’s output. . The printer I use is Epson R290.

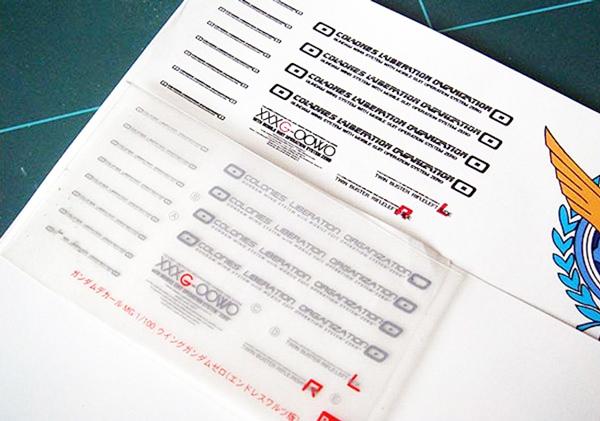

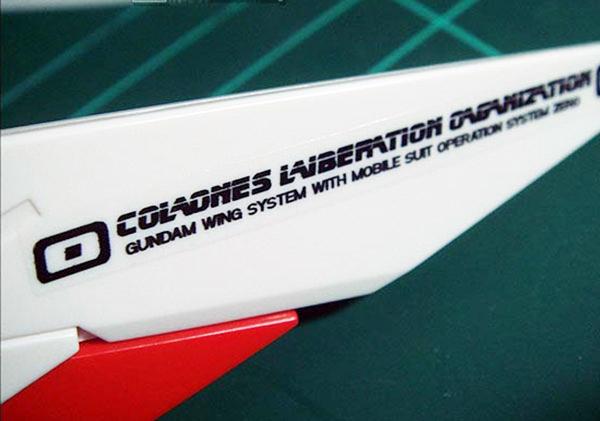

The contrast effect of output water transfer decals and Bandai pressure stickers.

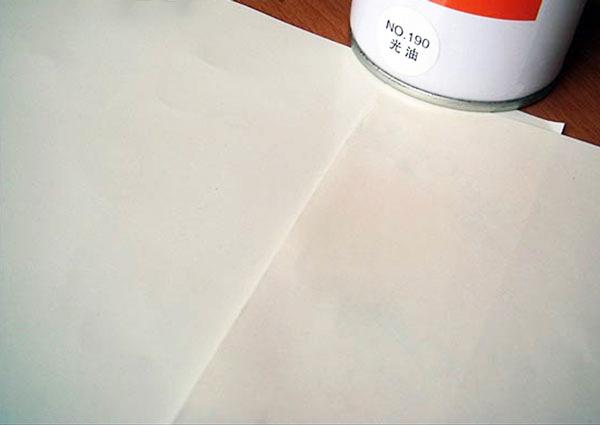

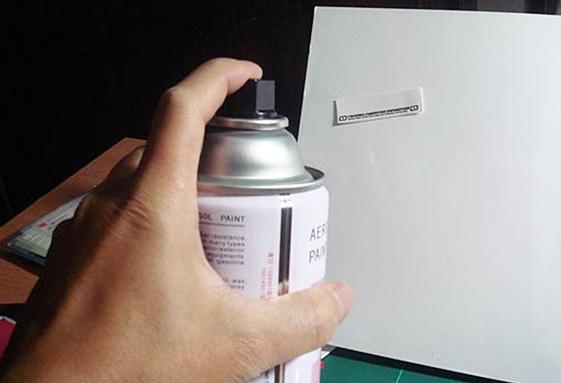

After the output, it will be coated with vanish.

The purpose of the varnish is to protect the printed ink, because generally the ink of the inkjet printer is water-based. It will turn off when dipping in water.

So it needs to put on transparent paint to make a protective layer.

We use the SANO brand vanish.

Cut the pattern and then spray the vanish.

When spray the vanish,it needs to spray evenly,not too thick or too thin.

Wait until dry after spraying. . A hair dryer can be used to “accelerate” (I do this).

After spraying,it can be seen that there is a layer of luster on the surface (use the vanish spray irrigation)

Wait until dry completely. Cut the pattern to fit the size.

Then the operation step is the same as the water transfer printing we generally use. Soak the water transfer decals into the water, so that the pattern can separate from the base paper.

Paste the pattern onto the airplane model.

Use cotton fiber to slowly push out bubbles and blisters inside until the pattern is smooth.

The water transfer effect.

Jim

Jim

Értékesítési vezető

Értékesítési vezető