TUBIG TRANSFER INFO

Ang water-soluble kola na layer ng tubig transfer decals awtomatikong dissolves kapag soaking sa tubig,at ang paghihiwalay ng sangkap na pangulay at transfer paper achieves ang paglipat ng mga pattern.

SINO TAYO

Tayo ay pabrika ng Intsik na kalidad na nagdadalubhasa sa industriya ng paglipat ng tubig. Aming layunin ay upang matustusan ang mga customer mataas na kalidad na tubig slide decal papel at paglipat ng decals para sa maraming mga application ng tubig.

BAKIT PUMILI SA AMIN

Tayo ay may magandang kalidad,makatwirang presyo at pinakamahusay na serbisyo. Ating tubig slide decal papel at tubig transfer decals magkaroon ng matatag na kalidad,mabuting knockout bilis,at lumalawak ang rate. Maaari nating kaugalian hinihingi ninyo.

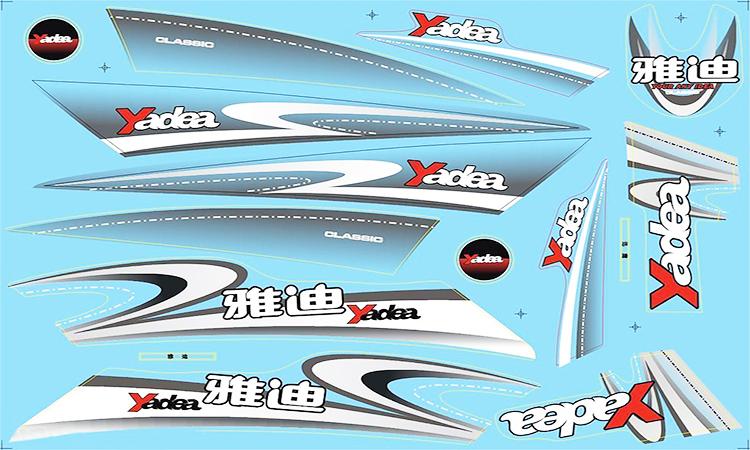

AMING PANGUNAHING PRODUKTO

Aming pangunahing produkto ay screen tubig slide decal papel, inkjet tubig slide decal papel,laser tubig slide decal papel,tubig slide decal papel para sa mga pansamantalang tatu,decals ng paglipat ng tubig para sa mga ceramic,salamin,helmet,at iba pa.High Quality Water Transfer Paper & Best Sublimation Paper Manufacturer!

WTP is special transfer paper factory in China. We manufacture three types of transfer papers. First is dye sublimation paper. Second is inkjet and laser heat transfer paper. And last one is the water transfer paper. That is, the waterslide decal paper. It also includes three kinds: screen printing decal paper, inkjet and clear decal paper.

Our thermal transfer paper has many advantages. For example, the ink transfer rate is high. Besides, the transfer effect is realistic. Fast drying speed. And the printing adaptability is strong. The paper is widely used in T-shirts, sportswear, cotton fabrics, tarong, at iba pa. With the inkjet printer and sublimation ink, the picture can be preserved for a long time. The usual formate is roll, A4 and A3. We are high quality sublimation paper manufacturer. If you need the best sublimation paper, welcome to contact us!

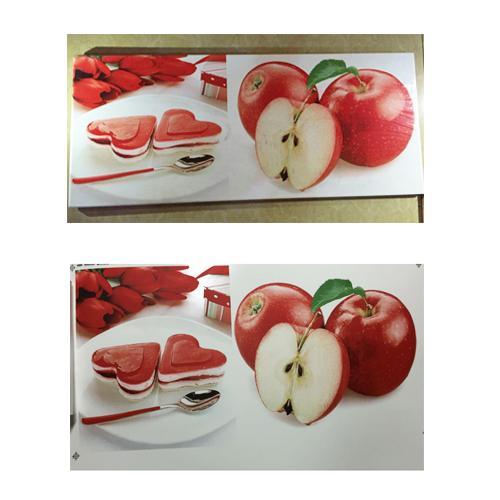

In addition, our water transfer paper release fastly. High stability. Moreover, there is no residue. We can use waterslide deca paper to print a variety of products. For example, use it on ceramics, salamin, helmet, kandila, toys, at iba pa. The pattern is clear and the color is bright.

Tampok na mga produkto

Ating kumpanya

We are professional water and sublimation transfer paper manufacturer in China. Our factory has introduced advanced equipment from France. It includes the longest coating machine and precise paper cutting machine in the industry. And we also imort high quality base paper and coatings. Sa kasalukuyan, our factory has mastered the mature technology of transfer paper manufacturing.

We mainly produce three kinds of transfer paper. That is best sublimation paper, iron on transfer paper and water transfer paper. Among them, thermal transfer paper has wide application in textiles, porcelain, advertisement banners, at iba pa. In addition, water transfer paper is suitable for various low temperature and high temperature glass & ceramic decals. Product quality is better than imported paper. And the prices are far lower than similar products.

Balita

We use a normal inkjet printer. Mirror print pattern onto T-shirt heat transfer paper. Firstly, use an electric iron to iron the clothes. Iron the T-shirt best sublimation paper. Then peel off the T-shirt sublimation transfer paper. Here we use light T-shirt transfer paper for illustration.

1. Light inkjet sublimation transfer paper application:

① Do not transfer this best sublimation paper to deep fabrics;

② Use 100% cotton or polyethylene fabrics;

③ Before transfer, it is best to wash the clothes. Prevent clothes from shrinking and causing deformation;

④ This paper is inkjet transfer paper. It can’t print with a laser printer;

⑤ Printer settings;

| Printer | Paper Type Setting | Printing Quality |

| HP Deskjet 600 | Special paper | normal |

| HP Deskjet 700, 800, 1000C & 1100C | Premium paper | nomral |

| Canon BJC printer | t shirt iron on transfer paper | default setting |

| Espon stylus color & photo stylus | ordinary paper | normal |

| Lexmark 1000, 1020, 2050 & 3000 | Heat transfer paper | High print quality |

⑥ Print the images. Dry for 15 minutes before transferring.

2. Hot stamping machine transfer application

① Wait until the image is completely dry. Trim around the image and leave about 1/8″ of the side;

② Transfer temperature: 177-190 degrees. Panahon: 5-8 segundo;

③ Mirror the print pattern. That is, the white side faces the fabric during transfer;

④ After transfer, immediately tear off the back paper. NOTE: The sublimation transfer paper may be hot.

⑤ Just cool the clothes.

3. Iron on transfer application

① Firstly, place the best sublimation paper on a flat surface. Get a cloth ready. Iron with an electric iron. Cover the fabric to the back of the inkjet transfer paper;

② Secondly, wait until it is completely dry before trimming the image;

③ Thirdly, set the iron to the highest temperature (cotton or linen). Do not add water and steam;

④ Before the transfer, iron the fabrics with an electric iron. Make sure there are no wrinkles;

⑤ Start mirror printing the patterns. That is, print on the white side;

⑥ Sometimes, the image is smaller than an electric iron. At this time, press and hold for about 10 segundo. Tear off the inkjet transfer paper immediately;

⑦ But sometimes the image is bigger than the iron. So start with one corner first. Constantly moving the iron for at least 30 segundo;

⑧ Then press different places in turn. If A4 sublimation transfer paper, the whole pressing process will take at least 2 minuto;

⑨ Take away the iron. Let the transfer paper cool for about 10 segundo. Ulitin ang mga hakbang 7 at 8 again. The whole process takes about 30 segundo;

⑩ Finally, take away the iron. Just tear off the backing paper.

4. Washing and drying

① The first wash should be after 24 oras. In order to better fix the pattern on the fabric;

② Wash with cold water. Do not use detergents with bleach;

③ Before washing, turn the pattern inside;

④ It is best to wash by hand separately. Do not soak for a long time. You can dry at low temperature.

Sublimation ink is a type of thermal transfer ink. The dye inside will sublimate after heating at high temperature. So the ink sublimates inside the substrate. Usually we print the ink onto the sublimation transfer paper. Then heat the best sublimation paper. Finally it can transfer the patterns onto the items. As sublimation paper manufacturer, we can also supply the ink.

The best sublimation paper ink can be suitable for many items. For example, we can use sublimation transfer ink and paper on materials such as porcelain, metal, silk, and chemical fiber fabrics. It can realize photo quality. It has wide application in apparel printing, large-scale digital inkjet printing system, heat transfer banners, and advertising flags, at iba pa.

What is dye sublimation ink?

Digital inkjet technology plays a important role in the field of textile printing. In fact, it includes dye-based inks and pigment-based inks. Although the latter has good sunlight fastness, it has insufficient adhesion to fabrics.

Therefore, textile inkjet printing usually uses dyes as colorants. Dye ink can be divided into three types. That is, reactive dye inks, acid dye inks and disperse dye inks. The former two inks are suitable for cotton fabrics, silk fabrics and nylon fabrics. Disperse dye inks are mainly used for polyester fiber fabrics. We can supply best sublimation transfer paper and ink.

The ink mainly composes of binder and sublimation dyes. The function of the binder is to disperse the dye evenly. So make the dye have viscosity and fluidity to suit for printing. And it make the dye fixing on the sublimation transfer paper.

Generally, there is an intermolecular force between the dye gas and the fiber. And it can diffuse into the fiber. So there will be no glue feeling. And the patterns are not easy to fall off. Besides, it has good air permeability. But it is not compatible with silk and pure cotton fabrics.

Performance requirements for inkjet printing inks:

① Firstly, the ink can produce high-quality patterns on the medium;

② Secondly, it needs has good light fastness and wet fastness;

③ Thirdly, the ink should not be blocked. The particle size should be below 1μm;

④ It needs to store the best sublimation paper ink for a long time. Besides, the printing effect should be not affected.

⑤ The physical properties of the ink are within range. For example, viscosity, electrical conductivity and surface tension can’t exceed the limits.

⑥ Non-toxic, safe and non-flammable.

How to choose the sublimation transfer ink?

It transfers the image to the product. Therefore, the restoration rate of color is important. The recovery rate of good ink can reach 90%. After transferring, the image on the best sublimation transfer paper is close to white. So the color saturation of the image is very good. Besides, the color is relatively bright.

Secondly, the sublimation ink with large particles is easy to cause the printer to block. And the image isn’t detailed enough either. We can see the graininess clearly with a magnifying glass.

Finally, some bad black ink are a bit purple. Black ink is the most prone to color casts. So you can print a black color block first. See if the transferred color is black. This is also an important indicator to directly judge the ink quality.

Clear t shirt transfer paper is also namely light fabric transfer paper. It’s suitable for white or light colors clothing. But dark color sublimation transfer paper suits for black or dark garments. In fact, they both belong to iron on transfer paper. Besides, both have a thin film. And they are also usually inkjet transfer paper. Of course, there are also laser transfer paper. Why need two kinds of heat transfer paper for different textiles? Which is the best sublimation paper?

Because each has its own advantages. Light colored transfer substrates are transparent. So it can only print white or light t-shirts. And it’s very breathable. But the dark sublimation paper has a layer of white. The purpose is to clearly reflect the true color of the pattern. In addition, dark transfer papers are generally unbreathable. So there is no the best sublimation paper. It needs to know what color of your shirts.

1 .Clear heat transfer paper

It’s specially for light cotton T-shirt. It is different from ordinary iron on transfer paper. Specifically, we use it to print light T-shirt with over 30% cotton content.

(1) Clear inkjet transfer paper specifications:

Pangalan ng produkto: iron on transfer paper clear (cold peel/hot split);

Main sizes: A4 (210mmX297mm), A3(297mmX420mm), A(8.5”X11”), B(11”X17”);

Applicable ink: ordinary water-based dye or pigment ink, sublimation ink, eco-solvent ink;

Aplikasyon: t-shirts, mouse pads, sportswear, hat, at iba pa;

What fabrics to print: light-colored pure cotton, semi-cotton or polyester, chemical fiber;

(2) Features of light fabric transfer paper:

The transfer pattern is soft to the touch. Stretching resistance and good breathability;

Vivid and realistic colors. Good transfer effect;

Suitable for color inkjet printers. Wider applicability;

Not only can print T-shirts, but also other fabrics, such asjeans, jackets, at iba pa.

The operation is simple, convenient and fast. The clear best sublimation transfer paper doesn’t need plate-making. Moreover, there is no quantity limit.

(3) How to apply iron on transfer paper light fabric?

① Firstly, print the image on the best sublimation paper. Tala: must print the reverse picture;

② Secondly, put the image on the side of the clothes. And spread over clothes;

③ Thirdly, let the temperature of the ironing machine up about 185℃. That is 330 degrees Fahrenheit. Then press down on the ironer. Stress as much as possible. Afterwards, pull up the ironer after about 20 segundo. Finally, peel off the liner of clear heat transfer paper. Kind note: the iron on tranfer paper has three types. That is, hot split, warm and cold peel.

2. Dark iron on transfer paper

We often have to print on black or dark fabrics. At this time, need to change its properties. So as to have the properties of white. Thus, dark sublimation transfer paper is actually a layer of white film. It has an inkjet coating on it. Therefore, it can absorb thermal transfer ink to form an image. And it can be attached to the object at high temperature.

(1) Specifications of t shirt transfer paper dark fabric

Paper name: inkjet transfer paper for dark fabric;

Mga pagtutukoy: A4(210mmX297mm), A3(297mmX420mm), 8.5”X11”, 11”X17”, 42cmX30m/roll.

What ink to use: ordinary water-based dye or pigment ink;

(2) Characteristic of dark color best sublimation paper

① Directly use the inkjet printer. We can print images easily on the coating side of dark transfer paper. It can fully restore the color and sharpness of the image. Not require color correction.

② Completely eco-friendly. The transfer process will not affect human health.

③ The picture is flexible. Pulling is not easy to tear. Washing water does not fade.

④ We can transfer on pure cotton and linen t-shirts. Besides, the best sublimation paper can also suitable for denim & chemical fiber fabric.

(3) How to use the dark iron on transfer paper?

① Firstly, print the front of the picture on sublimation transfer paper;

② Secondly, tear off the backing paper. Leave the thin layer of adhesive film with the picture. The side with the picture is facing up. Then put it on the textiles;

③ Thirdly, use a very thin release paper to spread on the film;

④ In the end, turn on the ironer. Bring its temperature to around 185 degrees. Hot stamping for about 20 segundo. Then pull up the ironer. Finally, peel off that release paper.

Tala: The above temperature and time are not absolute. You can also test the best sublimation paper by yourself.

In fact, both of them are thermal transfer printing. The principle is generally the similar. Transfer the patterns to the fabrics by heating. We manufacture the best sublimation paper.

What is iron on transfer paper?

Compound the pattern on PET film on the fabrics by the adhesive layer. It’s not penetrating into the textiles. Rather, it is printed on the surface of the fabric. Iron on transfer paper is mainly suitable for clothes with very high cotton content.

Specific application process: print patterns of various colors on the PET sheet. Then apply hot melt adhesive to the back of the pattern. The glue can bond the patterns to the garments. Press and iron with a pressing machine at about 150°C. Finally, peel off the PET film. So it completes the heat transfer process.

What is dye sublimation paper?

WTP produce the best sublimation paper. It prints sublimation ink on dye sub paper. Then heat and pressurize sublimation transfer paper. Transfer the pattern to the items. So the ink dyes will penetrates into the fabrics.

Proseso: Print disperse dye ink on the best sublimation paper. Then use high temperature and high pressure. Transfer the patterns from the paper to the object.

Best sublimation paper vs iron on transfer paper

1. Stamping temperature and time are different

For the latter, thermal transfer temperature is between 130~150℃. The time is about 6~10 seconds. But the sublimation temperature should be between 200~230℃. And time is about 15~20 seconds.

2. Application materials are different

Iron on transfer paper can be used on many fabrics. In addition to pure cotton textiles, it can also applicable in nylon, non-woven and polyester fabrics, at iba pa. It can be suitable light colored fabrics as well as dark or black.

However, best sublimation paper cannot be used for pure cotton clothes. It can only suitable light color or white polyester fabrics. The more polyester-containing ingredients, the brighter the color. In addition, sublimation transfer paper can also be used on other solids. For example, we can use it to ceramic cups, aluminum bottles, at iba pa. Of course the objects should have coating layer.

In addition, iron on transfer paper are usually A3 and A4 sizes. Mainly used for small batch production. But best sublimation paper is mainly in rolls. Mainly used for mass production.

3. The touch feeling after hot stamping is different

The iron on transfer paper has adhesive on the back. So it feels bumpy to the touch. It’s like something attaching to the surface of the fabrics. It feels a little hard to the touch. But for the best sublimation paper, the ink penetrates into the textiles. So it doesn’t feel glue to the touch. Relatively soft and good breathability.

4. Washing fastness is different

For heat transfer paper, the pattern is attached to the garment surface. But for best sublimation paper, the pattern is seeped into the fabrics. Therefore, the washing fastness of the former is not as good as that of the latter.

5. Working principles are different

Substrates for the best sublimation transfer paper must be polyester fibers. Its transfer principle is like this. That is, there are tiny voids in the polyester fibers. Raise the temperature to about 200°C. Vigorous exercise in the amorphous zone. The gap increases. So it creates conditions for gaseous disperse dyes to enter the fiber.

On the other hand, the dye sublimates into a gaseous state. The gaseous dye moves around the polyester fibers. Then they diffuse into these voids. As the temperature decreases, the dye molecules condense. So achieve the coloring effect. Only polyester fibers have this property.

This method cannot be used directly for cotton fabrics. Because the amorphous area of cotton fibers has very small voids in the dry state. And it’s not thermoplastic. When the temperature rises, its amorphous region does not form a so-called “liquid layer”. Besides, it is not attractive to gaseous disperse dyes by itself. So it can’t use the best sublimation paper for cotton clothes.

Dye sublimation is different from other large-format inkjet printing processes. Not only does it produce vivid colors, but it also present very rich image details. Firstly, print the opposite image on best sublimation paper with a digital printer. Then this image transferred to the substrate using thermal energy. This substrate can be chemical fiber or polyester material.

It uses sublimation ink. And use these inks to expand the color gamut of your prints. Sublimation turns solid dyes into a gaseous state. There is no liquid process in the middle. For example, dry ice will turn into a mist at room temperature. This is a typical sublimation process.

What’s the working principle of sublimation transfer paper:

Print sublimation inks on the heat transfer paper. At 356~410°F, the ink will transfer to the fabric. That is, 180~210℃. Because of the high temperature and pressure, the dye will turn into a gas. Eventually it will cure on the textile.

In addition, heat can open small pores in the surface of polyester products. It allows the gas dye to penetrate the material. The sublimation ink cools down when the heating stops. Finally, it will become solid. At the same time, the voids on the polyester material are also closed. If apply correctly, the patterns will not fade.

Sublimation transfer printing process:

Thermal sublimation generally includes the following three processes.

(1) Before the transfer process:

All dyes are in printing film on best sublimation paper. The dye concentration in the fabric and air gaps is zero. The size of the air gap depends on the fabric structure and transfer pressure.

(2) During the transfer process:

Apply heat and pressure to the sublimation transfer paper. At this time, the dye begins to volatilize or sublime. When the fabric reaches the transfer temperature, dye adsorption begins. This will continue until reach a certain saturation value.

The transfer of dye from the best sublimation paper to the fiber is continuous. Therefore, its adsorption rate depends on the rate of dye diffusion.

(3) After the transfer process:

After transfer, the dye content on sublimation paper decreases. The remaining dye migrates to the inside of the paper. The amount of dye remaining depends on the vapour pressure of the dye. Sublimation generally does not require wet processing. So it’s energy-saving. At the same time, it also reduces the load of sewage treatment.

Transfer paper application on dye sublimation printer:

Printers use solid pigments. After heating, it is directly sublimated to the gas phase. Then we transfer them to the fabric to generate an image. Dye sublimation printing utilizes thermal induction technology. When printing, the YMCO three colors dye is heat treated with a protective film. Then print on the sublimation transfer paper.

The source of color dyes is the ribbon. Generally there are three colors ribbons. That is, yellow, magenta and cyan. Plus a protective film. The ribbon is set on a rotating drum. And there are many semiconductor heating elements. These heating elements make up the print head. The ribbon passes through the thermal print head. Directly sublimates into a gaseous state. Afterwards, they are sprayed onto the print medium. Finally, it forms the colors.

Each heater head can form 256 temperatures. So there are many degrees of color sublimation. In addition, it uses three kinds of color pigments. Namely yellow, cyan, magenta colors. There will combine as many as 16.7 million colors.

So the dye sublimation transfer color is vivid. And it’s layered. Besides, it can show subtle color differences. Dye sublimation transfer paper truly achieves photo quality. Plus it has a protective layer. So best sublimation paper has great advantages. It’s better than other printing technologies in waterproof and UV protection.

In summary: Sublimation paper has a unique working principle. High-quality output is the biggest highlight. Dye sublimation transfer printing has high printing accuracy. In terms of photo preservation, the preservation period of photos printed by thermal sublimation printers is truly permanent.

It’s simple to use the dye sublimation paper. Best sublimation paper can be used for T-shirts. And it is also suitable for mugs, phone cases, salamin, woods, PCB, at iba pa. In fact, their application methods are similar.

DIY T-shirt Sublimation Transfer Paper Appication Tutorial

1. Prepare the machine and all materials:

① Computer: there should be with photoshop, corelDRAW and other image editing software;

② Sublimation printer: recommend Epson inkjet printer. Here we use the six-color printer epson290. Of course, 230, 270, at iba pa. are also available.

③ Sublimation transfer ink: special ink for heat transfer! This is a lightfast and waterproof ink. And it has high color reproduction ability.

④ Heat transfer machine: here we use the JM1-310 heat transfer machine. It’s also namely iron on press machine.

⑤ Sublimation transfer paper: we use the light t-shirt transfer paper. The fastness is very good. And this is best sublimation paper. It basically can’t feel the glue layer.

Suitable for transfer printing: T-shirts, textile, garments (100% cotton, 50% cotton, chemical fiber, linen, wool, synthetic fiber. Especially suitable for all bright color garments)

⑥ T-shirt: we use the T-shirt with cotton over 180 grams.

2. Print the picture onto thermal sublimation transfer paper

① Firstly find a photo that you are satisfied with. Then take a sheet of the best sublimation paper and print. Pay attention to distinguish the front and back. In addition, light heat transfer t-shirt paper should be mirrored. But dark t-shirt transfer paper does not need mirroring.

Before printing, also adjust the printer settings: set it to high-quality glossy photo paper. The photo type is Premium Photo.

② Before printing, test whether the print head is blocked or not! Print the test pattern first. See if there is any disconnection!

Printing —— don’t touch it just after printing. The sublimation ink may not be dry yet.

Select the “Nozzle Check” tool if blank or light print areas appear in the printout.

If the print quality is degraded, or the nozzles are clogged, use the “Print Head Cleaning” tool.

3. Start thermal transfer

① Firstly, raise heating temperature to about 200°C. Different sublimation transfer papers may need different temperatures. For specific transfer temperatures, ask your thermal sublimation paper manufacturer.

② Secondly, put the T-shirts. There must be no wrinkles. Press it with a heat transfer machine first! Make it flat.

③ Thirdly, put the printed pattern in the corresponding position! This time we print light t-shirt. So use light iron on transfer t-shirt paper. Place the image down!

The location and direction must be right! Otherwise it will waste the best sublimation paper.

④ After everything is OK, press down the iron on press machine. Be sure to press hard! Countdown to 14 segundo. Or set it up ahead of time on the heat transfer machine! When finishing, lift the thermal transfer panel up!

⑤ Take the t shirt out. Let cool down a bit. Then tear off the heat transfer paper. Finally, the pattern layer is printed on the t-shirt!

4. Test thermal transfer quality

① Put the T-shirt into the washing machine: mainly to test the reliability of the sublimation transfer paper layer. Or test the washability of the ink.

② Actual wear test: only you can test it yourself!

Sublimation transfer paper is also a type of heat transfer paper. It heats the pigment molecules into the textile. There are three elements for realizing sublimation. That is, sublimation ink, printer and dye sub paper. As best sublimation paper manufacturer in China, we produce facbric transfer paper rolls and sheets.

Firstly print patterns onto thermal sublimation paper. Then put the paper onto the fabrics. Under heat and pressure, the dye will be transferred to the garment. This is because disperse dyes sublime at high temperatures. Generally, the thermal transfer temperature is about 200°C.

Specifications of best sublimation paper

Pangalan ng produkto: white sublimation transfer paper;

Uri ng papel: fast/quick/instant dry, adhesive/sticky/tacky, high speed;

Paper weight: 35GSM, 50GSM, 60GSM, 70GSM, 80GSM, 90GSM, 100GSM, 120GSM, at iba pa;

Width: 0.21m, 0.3m, 0.42m, 0.48m, 0.61m to 1.85m (custom);

Dye sub paper size: A3, A4 sheet, roll,jumbo roll,customizable;

Sheet paper size: 8.5 x 11, 8.5 x 14, 8.5 x 13, 11×17, 11×17, 12×12, 13 x 19, 15×15,

Ordinary printer: inkjet printer, such as Epson C65, 830u, R210, R310, R800, 1520K,EX3, 1290, 2100,at iba pa;

Wide format inkjet printers: EPSON 3000, 4000, 4000HS, 7600, 9600, 10600; Roland, Mimaki, Mutoh, Encad, at iba pa.

What ink to apply: sublimation ink (disperse dye ink);

Hot pressing temperature and time: about 220℃ and 10~30 seconds;

Paper application: fabric, textile, garment, clothes, polyester fabric, chemical fiber, tarong, bottles, ceramics, salamin, at iba pa;

Thermal transfer conditions

(1) Conditions for transferring printing dyes

① Firstly, the dye must be fully sublimated about 200°C. It is then fixed to the fiber. At the same time, it needs to have good washing and ironing fastness.

② Secondly, the dye can fully convert into a gas-phase dye macromolecule. Then agglomerate on the fabric surface. Besides, it can diffuse into the fiber.

③ In addition, the affinity of dyes to best sublimation transfer paper is small. The affinity for fabrics is greater.

④ Finally, the dye should have a bright color.

(2) Thermal transfer paper should have the following conditions:

① First of all, there must be enough strength;

② Secondly, the affinity for color ink should be small. However, dye sub paper should have good coverage for the ink;

③ In addition, deformation and yellowing should not occur during the printing process.

④ Finally, digital transfer paper should have proper hygroscopicity. Poor hygroscopicity will cause the color ink to match the color. But, excessive hygroscopicity will cause deformation.

Sublimation transfer paper application:

Thermal transfer paper is mainly used in polyester fabrics. Or use it on fabrics with more than 80% polyester. In addition, we can also apply it on other materials.

But these materials need to withstand temperatures above 200°C. And the surface should be with sublimation coating. For example, use the paper for mugs, porcelain plates and photo frames.

The current applications of best sublimation paper are:

① all kinds of chemical fiber fabrics, such as T-shirts, sportswear, cycling clothes, etc.;

② Metal, kahoy, ceramics, salamin, PVC, leather PU, etc.;

③ DIY personalized market. Halimbawa, use the dye sub paper for dyeing, decoration, handicrafts, gifts, advertising;

④Another important application area is colored flag printing;

Dye sub paper features:

① High printing efficiency

It can use computers for image processing and design. And print patterns on paper by a high-speed inkjet printer.

Therefore, there no needs plate-making process. Also greatly saves production time and cost. It’s an alternative to screen printing.

Moreover, for complex patterns,we can change at will. So sublimation transfer paper is very efficient.

② Vivid printing patterns

The sublimation transfer paper pattern is continuous. So it can clearly reflect the design pattern and colors. The colorful patterns are rich in layers. Besides, the product is waterproof and anti-aging.

③ The print feels very soft and comfortable

The dye diffuses into the polyester fibers. Therefore, we can’t feel the presence of the ink layer. Din, the ink dries during the transfer process. So the life of the image is as long as the life of the product itself. There will be no wear and tear of graphics.

④ Environmental friendly

After printing, it is already the finished product. So don’t need no post-processing, such as steaming, soaping, and water washing. Production is highly flexible.

There is no waste water and other pollution. So best sublimation paper is good for environmental protection.

How is sublimation paper manufactured?

Sublimation transfer paper usually consists of two parts. That is , base paper and coating. Firstly, apply the coating composition to the base paper. Then dry it in multiple ovens. Finally, we get the finished transfer paper after winding.

The production steps are as follows:

① First, provide the original base transfer paper.

② Next, prepare a coating composition. Disperse the pigments at high speed for 30 minutes at 2000r/min. Then add the intumescent adhesive and bio-based powder. Susunod, stir at 1000 r/min for 30 minuto. And it obtains the coating composition.

③ Finally, apply the coatings on the surface of the base paper. After drying, we get the best sublimation paper.

Specific examples of manufacturing sublimation transfer paper:

① Prepare 38 g/m2 base transfer paper.

② Prepare the coating composition

Bio-Based Powder 40 portions. 60 portions pigments. 40 portions of intumescent adhesive.

Among them, the bio-based powder is tapioca oxidized starch. The particle size is 18um.

The pigment is kaolin. The particle size is 0.5um.

The intumescent adhesive is sodium alginate and polyvinyl alcohol.

Their mass ratio is 1:5.

The solid content of the coating is 50%.

③ Then we adopts roll coating method. The coating amount is 8g/m2. And start hot air drying with temperature 70 ° C.

④ Finally, print on the best sublimation paper. Then make transfer test.

The drying time after printing is 8s.

In the end, we apply 300% volume sublimation inks CMYK on fabrics. Their transfer rates are 85.0%, 87.1%, 85.8% at 86.3% respectively.

So the ink dries fast on our sublimation transfer paper. And the transfer rate is high. Therefore, it can garantee the quality of the transfer pattern. We are high quality sublimation paper manufacturer. Welcome to inuqire us.

In fact, sublimation paper is also a kind of transfer paper. But it is not the same as transfer paper. In addition to dye sub paper, transfer paper also includes waterslide decal paper and iron on transfer paper.

1. Sublimation transfer paper vs waterslide decal paper

Although they are both transfer papers, they are very different.

① The working principles are different:

The former is to first print the dye inks onto the paper. Then they will sublimate at a high temperature of 200°C. Finally it will seep the patterns into the fabrics.

The latter contains hydrosols. So water transfer paper is particularly sensitive to water. Firstly, put the decals into the water. Wait about 30 segundo. Then the hydrosol will decompose. Therefore, the pattern on the stickers will be separated from the base paper. So we can transfer the patterns onto products such as ceramics.

In summary, water is a necessary medium for water slide decal paper. It must to use water to achieve transfer printing. However, best sublimation transfer paper does not use water.

② The specifications are different:

Best sublimation paper is mainly in rolls. Only A3 and A4 are in sheets. Besides, there are many specifications. It includes thin and thick paper, such as 35gsm, 50GSM, 70GSM, 90GSM, 100GSM, 120GSM, at iba pa.

The length can be custom at will. The width is generally from 0.21m to 1.85m. And it can also be divided into quick dry paper and sticky paper.

In contrast, water transfer paper is primarily in sheets. A3 and A4 are mainly suitable for inkjet and laser printing. The screen printing size is larger, such as 500*700mm, 390*540mm.

It has relatively few specifications. Commonly used are 170gsm, 180gsm and 180gsm. In addition to white, waterslide decal paper is also available in blue.

③ Their applications are different:

Compared to sublimation transfer paper, the latter has a wider applications. Water decal paper can be used for most objects. Besides, it doesn’t require coating. Common applications are below. That is, ceramics, salamin, helmet, kandila, at iba pa. Temporary tattoos are also water decals.

In addition, water stickers also include low and high temperature. For example, wine bottle stickers need to be baked at 160°C. But it needs to bake ceramic decals at 800°C or 1200°C.

Of course, some water stickers cannot be baked. For example, we can’t bake furniture and candle decals. It requires natural drying.

But best sublimation paper is mainly used for fabrics. That is, chemical fiber fabrics and polyester fibers. For example, we often use it in T-shirts, sportswear, flags, at iba pa.

Of course, sublimation transfer paper can also be used for ceramics. But ceramics have to be with coating. After application, it requires no high temperature baking.

2. Sublimation transfer paper vs iron on transfer paper

In fact, both of them are heat transfer paper. Both need to transfer at high temperature. But there are many differences.

(1) Their principles are different

The former uses the dye ink. It is complete solution. The dye becomes gaseous at high temperature and pressure. Finally, inks diffuse in the fibers of the substrate.

Best sublimation paper does not change the texture of the substrate. Therefore, the sublimation printing feels very soft to the touch. And it can achieve photo-level printing effect. Sublimation is mainly for chemical fiber and polyester materials.

But heat press paper uses weak solvent ink. It is a semi-solution. It is not directly related to cotton fibers. So print the ink on the transfer paper in advance. Then do the printing.

It is actually a transparent film with glue. The principle is to transfer the clear film on the paper to the fabric. So the feel of heat transfer is poor. Besides, the washing fastness is not high.

(2) Their applications are different

Iron on transfer paper is mainly used in pure cotton clothes. It includes two kinds. That is, dark and light transfer paper. When the fabrics are black, use dark heat transfer paper. On the contrary, use the latter one. And there also includes cold peel and hot peel transfer paper.

The application of best sublimation paper is wider than that of heat transfer paper. Except cotton, sublimation transfer paper can be used in many places. Such as mugs, phone cases, ceramics, bottle, salamin, kahoy, at iba pa.

In addition, the latter is usually A4 and A3 sizes. So mainly used in small batches. But the former is in rolls. Then we usually use it for mass production.

Jim

Jim

Sales Manager

Sales Manager